Positioning Wrap Around Round Bottle Labeling Machine

Model: Y-200

Designed for vertical point-to-point labeling of round bottles and conical bottles.Positioning adhesive labeling machine.

- Speed:0-60 bottles /min

- Application Bottle Size:Φ35-80 mm

- Applicable Label Size:L:15-100mm,W:15-150mm

- Power Supply:3KW, AC220V, 50/60HZ

- Technical Parameter

- Electrical Parameter

- Application Samples

| Machine Parameters | |

| Applicable bottle diameter | Φ35-80 mm |

| Labeling speed | 0-60 bottles /min |

| Labeling accuracy | ±0.5mm ( except packaging material error ) |

| Product broken rate | < 0.01 % |

| Labeling pass rate | > 99.9% |

| Power supply | 3KW, AC220V, 50/60HZ |

| Air consumption | 0.5Mpa,300L /min |

| Machine dimension | 2580*1300*1328mm |

| Total weight (approximately) | Around 300Kg |

| Self-adhesive label parameters | |

| Applicable label material | Transparent labels, coated paper & PE, etc. |

| Applicable inner diameter of the label roll | φ76mm |

| Maximum label roll outer diameter | Φ400mm |

| Applicable label size | L:15-100mm,W:15-150mm |

| Label spacing | 2-4 mm |

| Top/bottom margins on liner | 2 mm |

| Grammage | >62 g/m2 |

| Thickness | >55 μm |

| Tensile strength | Machine Direction : 16kg/25mm ,Cross direction: 7kg/25mm |

| Breaking strength | Machine Direction : 25g/sheet ,Cross direction: 31g/sheet |

| Transparency | 52% |

| Electronic control system | ||

| PLC | S7-200 smart | SIEMENS (Germany) |

| Power Supplier | LRS-100-24 ( DC24V/100W) | MEAN WELL (Taiwan) |

| Air switch | ic65N-c16A | Schneider (France) |

| Air switch | ic65N-c10A | Schneider (France) |

| Relay | MY2N- GS | OMRON (Japan) |

| Chassis unit | ||

| Main material | Stainless steel SUS304 | |

| Chassis dimension | 1200(L)×850(W)×1840(H) mm | |

| Case structure material | Stainless steel square tube SUS304 | |

| Outer sealing material | Stainless steel SUS304 | |

| Illuminated button ( red ) | XB2BA42C | Schneider (France) |

| Emergency stop switch | XB2BS542C | Schneider (France) |

| Threshold switch | SN05-N | ROKO (Taiwan) |

| Conveyor mechanism | ||

| Main material | Stainless steel SUS304, aluminum A6061, plastic steel chain plate, POM | |

| Conveying motor and reducer | 5IK60GN-YFT 5GN15K | TWT (Taiwan) |

| Conveyor Motor Inverter | FC - 051 0.37 KW | Danfoss (Denmark) |

| Labeling host head | ||

| Main material | Stainless steel SUS304, Aluminum A6061, POM | |

| Label pulling servo motor | SGM7J-08AFC6S | YASKAWA (Japan) |

| Label pulling servo drive | SGD7S-5R5A00B202 | YASKAWA (Japan) |

| Label stock sensor | PRK3C.T3/2N | Leuze (Germany) |

| Label detection sensor | LRD-2100 | LION (USA) |

| HMI | ||

| Main material | Stainless steel SUS304, aluminum A6061 | |

| Touch screen | PFXGP4402W | Proface (Japan) |

| Illuminated button ( green ) | XB2BA31C | Schneider (France) |

| Illuminated button ( yellow ) | XB2BA51C | Schneider (France) |

| Illuminated button ( red ) | XB2BA42C | Schneider (France) |

| Emergency Button | XB2BS542C | Schneider (France) |

| Rotary Switches | ZB5AK1253C | Schneider (France) |

Differential Bottle Separation Device

Configuration of the differential speed bottle separating mechanism requires no change parts; only positional adjustments of the various mechanisms are needed. Depending on customer requirements, an optional timing screw bottle separator can also be selected.

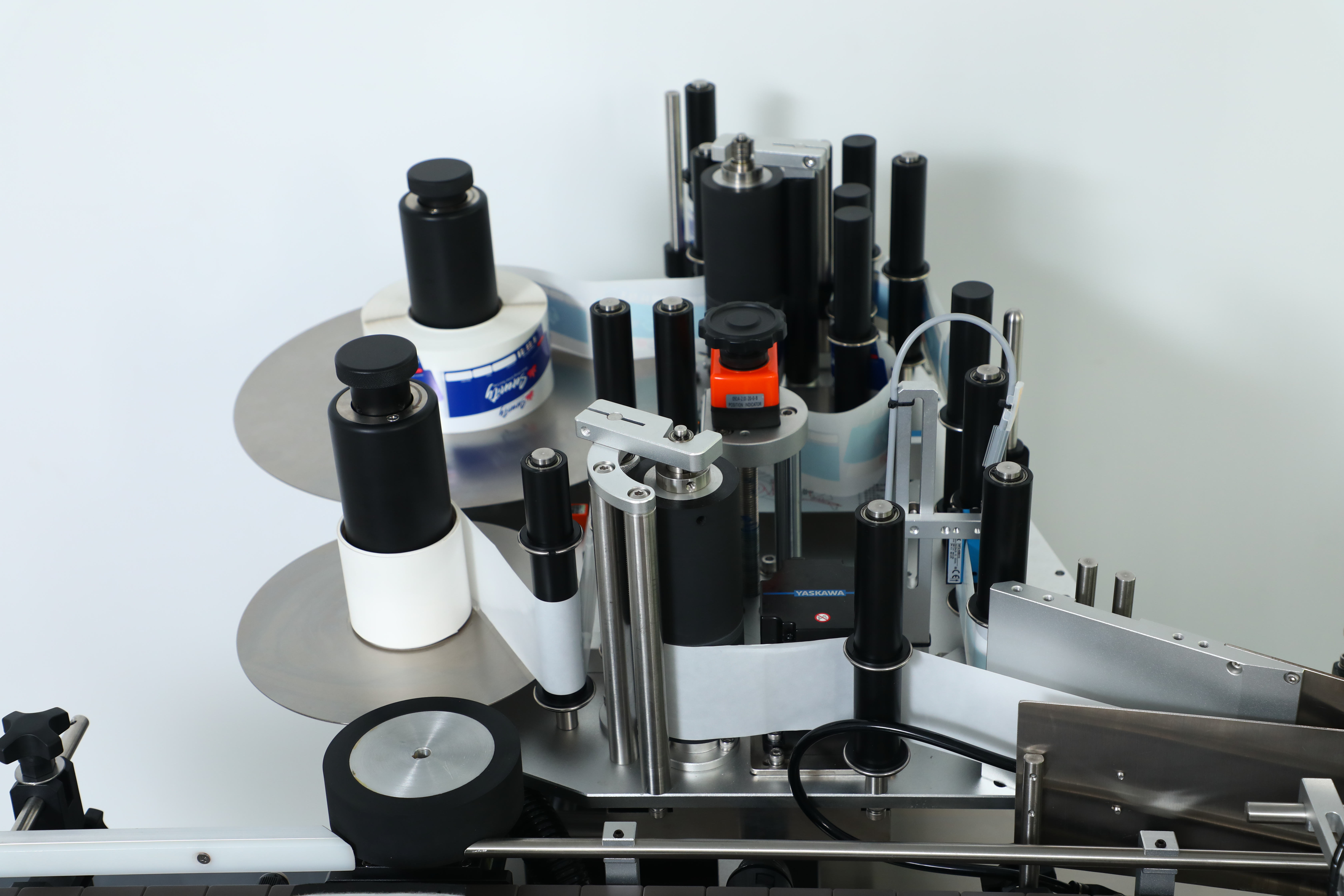

Labeling Host

The labeling head is the core component of the labeling machine that actually dispenses the label from its backing paper and applies it onto the product.

Our labeling machine's main head features a three-section design, consisting of the label feeding, label pulling, and backing paper rewind mechanisms, respectively. Each mechanism is controlled by a separate motor, ensuring fast and stable label transport.

Conveyor System

It is equipped with a belt conveyor system. This conveyor transports the products consistently and usually features adjustable speed control and guide rails to ensure proper positioning for accurate labeling.

Related Products

Main Features

Positioning Wrap Around Bottle Labeling Machine Manufacturer

The positioning labeling machine is designed specifically to apply labels to a precise, predetermined location or orientation on cylindrical containers.

- Round bottle labeling

- Conical bottle labeling

- Round cans labeling

consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.

The machine utilizes sensors (often photoelectric, fiber optic, or sometimes vision systems) to detect a specific feature on the bottle (such as a mold seam, handle, embossed logo, existing label, or a specific mark).

Delivers high accuracy in the vertical and horizontal placement of the label, minimizing skew and ensuring the label is positioned exactly as required on the bottle's circumference.

Labeling speed can usually be adjusted to match the throughput of the production line. Speed is often synchronized with the conveyor speed for seamless integration.

Ensures labels are applied smoothly and firmly, without wrinkles, bubbles, or edge lifting, contributing to a professional product appearance. Mechanisms often include label smoothing brushes or rollers.